Name. | ZTA powders |

| |||||||||

Desc. | White powders | ||||||||||

Tightly sealed with plastic film in PP drum. | |||||||||||

With typical advantages of low sintering temperature and uniform dispersion of two components; product processed with this powders have the characteristics of easily machining properties after firing, high strength, high toughness, high wear resistance, good corrosion resistance and high temperature stability. | |||||||||||

App. | Widely applied in production of ceramic insert of machining tools, mold, bushings, valve seat; wear resistant parts of textile machinery and other high performance structural ceramic parts. |

| |||||||||

Spec. | Grade | ZrO2(HfO2)+Y2O3 | Al2O3 | SiO2 | Na2O | BET | D50 | ||||

SZ-ZTA | 19-21wt% | 78-80wt% | 0.01wt% | 0.003wt% | 8-10m2/g | 0.6-1.0μm | |||||

Other impurities such as Si, Fe, Na, Al are controlled below 100ppm; | |||||||||||

| Suggesting forming method | dry and isostastic press | ||||||||||

| Typical Flexural strength | >550Mpa | ||||||||||

| Suggesting firing temperature | 1420-1450℃ | ||||||||||

| Typical firing density | >4.2g/cm3 | ||||||||||

| For more information please contact our professional sellers. | |||||||||||

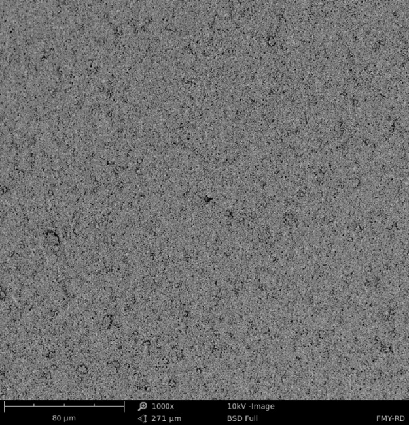

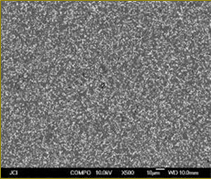

Photos. |

SEM of Sintered sample | SEM of Sintered sample | |||||||||

Remark. | Information showed above only for reference, prevail with the agreed quality standards after sale. Carefully read the MSDS document before using; Process performance may not be suitable for some specific circumstances, please contact our company professional guidance; Product can be customized according to customer specific requirements. | ||||||||||

ZTA powder

Prev:MgO-Stabilized zirconia powder

Next:ATZ powder